What we can Provide

CONSULTING SERVICES

- Interpretation of test results.

- Interpretation of standards and specifications, and guidance on applicability.

- Test plan development to meet particular specifications and standards.

- Test plan development for failure analysis.

- Test results analysis in failure analysis.

- Training in standard test methods.

- Training in specific test methods.

- Control charts development.

- Uncertainty budgets development.

- Materials Selection

- Materials Testing & Evaluation

- Materials Specifications

- Testing per ASTM Standards

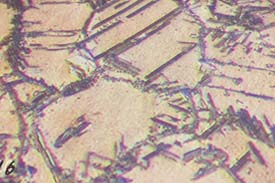

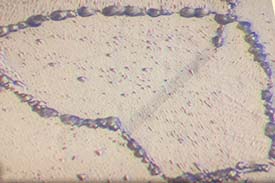

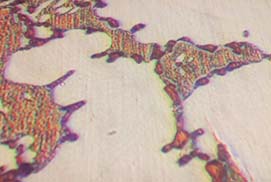

- Microstructure Analysis

- Chemical Analysis & Materials Identification

- Welding and Weld Evaluations

- Heat Treat Evaluations

- Failure Analysis

- Quality Management System setups

- Compliance with ISO 9001 and ISO/IEC 17025

- Metallurgical Laboratory Management

- Others – includes guidance in the following specialties; Optical Emission Spectroscopy, Scanning Electron Microscopy, Energy Dispersive X-Ray Analysis.

CONTRACT SERVICES

- Contract Metallurgist

- Contract Metallographer

- Contract Testing Witness

- Contract Metallurgy Lab Advisory

- Contract Failure Analyst

- Contract Metal Alloy Chemist

- Contract SEM/EDS Specialist

- Contract Quality Management Systems Specialist

- Contract Safety Management Systems Specialist

- Contract Metallurgical Laboratory Hazards Specialist

WITNESS & AUDITING SERVICES

- Witnessing mechanical testing including the following: Tensile testing; Hardness Testing (Rockwell, Brinell, Vickers, and Knoop), Impact testing, Bend test, Fracture test.

- Witnessing corrosion testing including the following: Susceptibility to pitting corrosion testing; Susceptibility to crevice corrosion testing; Susceptibility to Intergranular Attack.

- Witnessing chemical analysis including the following: Chemical analysis by optical emission spectrometry of various alloys; carbon and sulfur analysis by combustion; gas analysis by inert gas fusion method.

- Witnessing of failed component testing and analysis.

- Witnessing of scanning electron microscope analysis and energy dispersive spectroscopy of failed components.

- Auditing quality management systems per ISO 9001 standard.

- Auditing quality management systems per ISO 17025 standard.

- Auditing test procedures per referenced standards and specifications.

- Auditing equipment calibrations and verifications with certified reference materials.